Magnesium-Aluminum-Zinc alloy coated Galvalume Steel (GLX)

GLX is produced by alloying the aluminum, zinc, silicon and magnesium and then hot dipping it on a steel sheet.

It is designated to be suitable for the applications requiring high corrosion resistance.

The coated layer of GLX consists of 55% aluminum, 43.4% zinc and magnesium and 1.6% silicon.

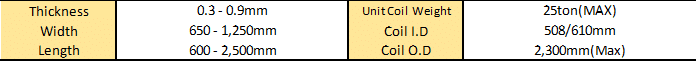

PRODUCT SPECIFICATION

The coated layer containing magnesium promotes generation of Simonkolleite (Zn5(OH)8CI2H2O) which stabilizes the self-sacrificial reaction of zinc.

The thin layer of Simonkolleite formed on the coated surface significantly delays corrosion of aluminum and zinc alloy coated layer.

The Al-Cr metallic compounds is formed on the interface between the material and magnesium alloy plated layer and the MgZn2-Mg2Si metallic compound, which is the corrosion resistqnce improving element, is mexed to show outstanding corrosion resistant property.

* Corrosion Resistance

The coated layer containing magnesium promotes generation of Simonkolletie which stabilize the self-sacrificial reaction of zinc. The thin layer of Simonkolleite formed on the coated surface significantly delays corrosion of aluminum and zine alloy cated layer.

The Al-Cr metallic compound is formed on the interface between the material and magnesium alloy plated layer and the MgZn2-Mg2SI metallic compound, which is the corrosion resistance improving element, is mixed to show outstanding corrosion resistant property.

* Heat Resistance

GLX offers outstanding heat resistance. Such characterstic is attributed from the high aluminum content(80% of surface volume) in the coated layer and makes it ideal for the application such as automobile muffler or electric oven which are exposed to high temperature for a long time

– Zinc plaed steel sheet: The recommended operating temperature is 230˚C or less, and discoloration is generated when it used at 250˚C or higher

– GLX: No discoloration is expected when used at 315˚C for a long period.Up to 370˚C is supported when it used intermittently.

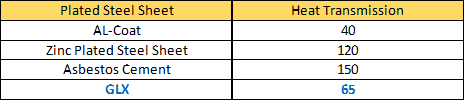

* Heat Reflexibility

The heat reflexibility of GLX is more than twice the zinc plated steel sheet and can save energy when used as the roof material or wall material without coating

Heat Transmission

* Coatability

Outstanding cohesion between the coated layer and paint.

PRODUCT SPECIFICATION

KS D 3033

AS 1397 : 2011

PRODUCT SPECIFICATION & AVAILABLE SIZE RANGE

BASE METAL SPECIFICATION

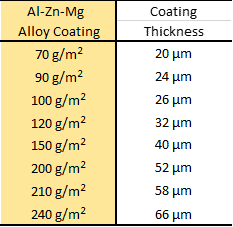

GLX COATING LAYER

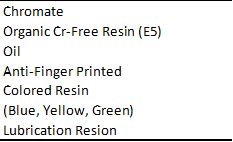

POST-PROCESSING

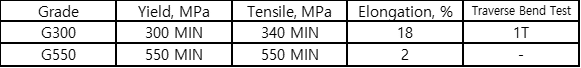

MECHANICAL PROPERTIES

Elongation on 80mm, %

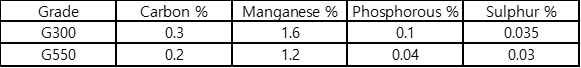

CHEMICAL COMPOSITION

ASTM SPECIFICATIONS - CHEMICAL COMPOSITIONS

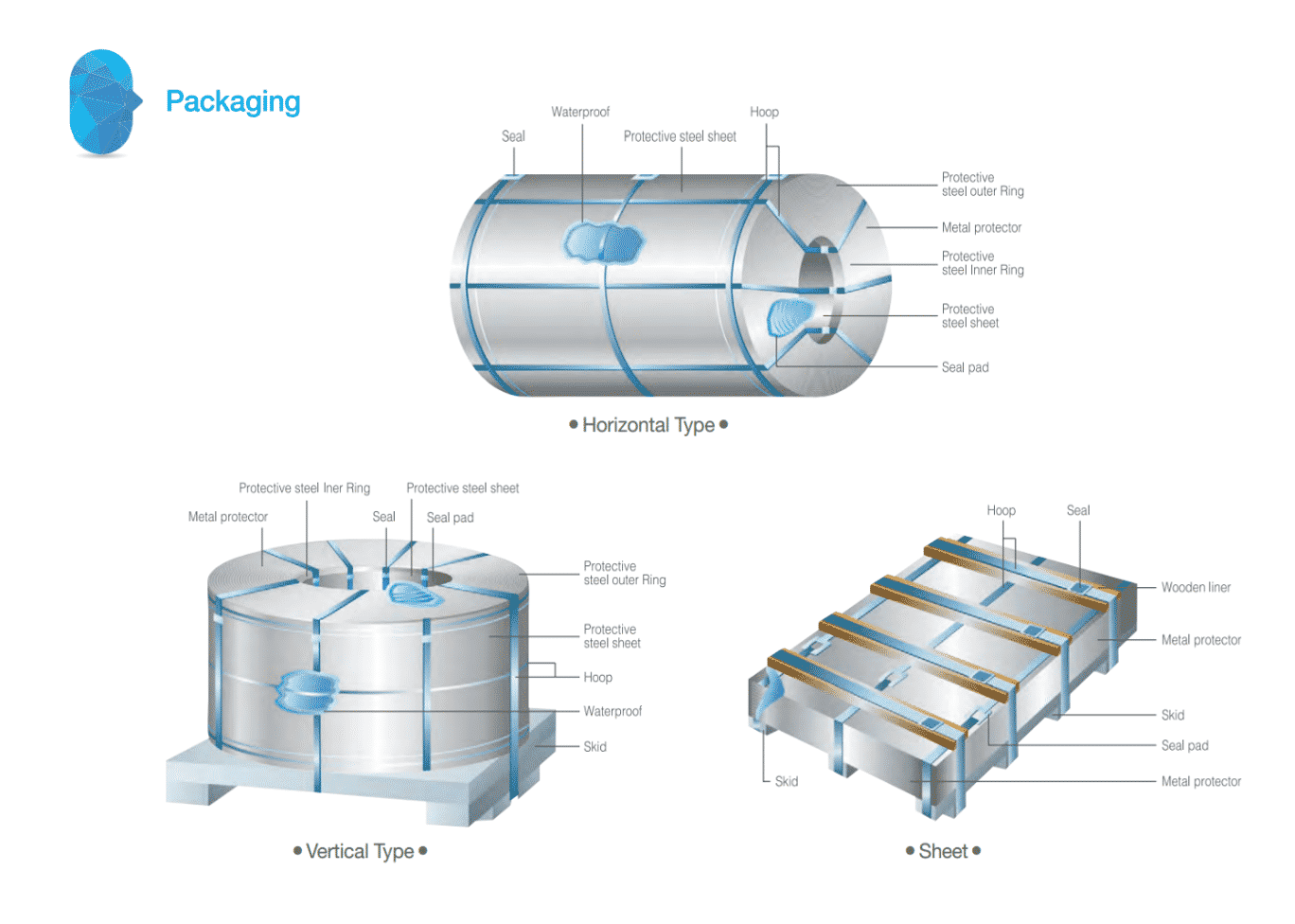

STANDARD EXPORT PACKAGING